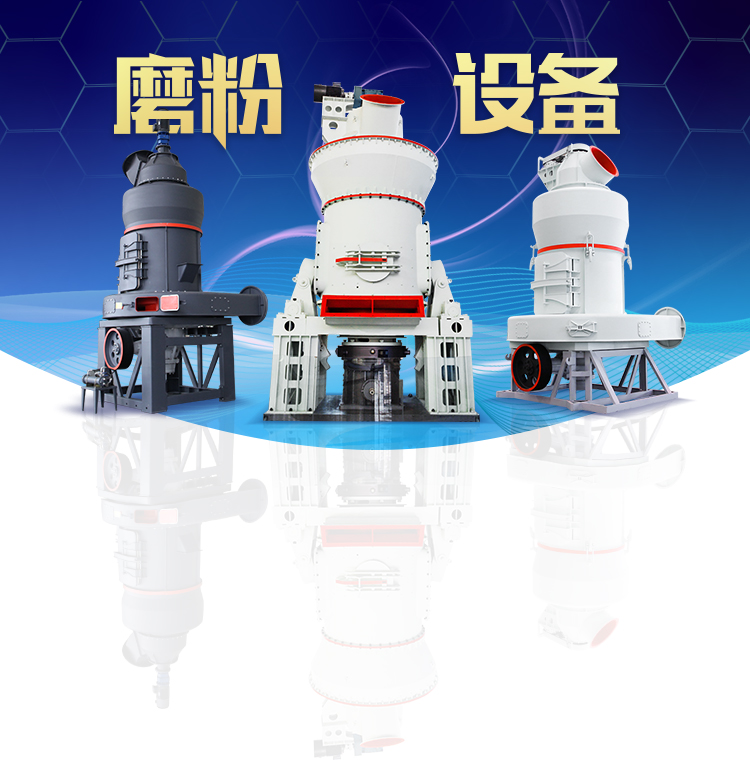

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

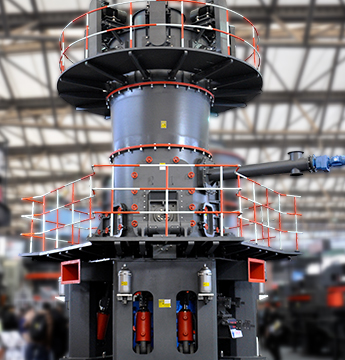

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Manufacturing Of Cement In Wet Process Ppt

Life Cycle Assessment of Portland Cement

2022年6月13日 Cement Manufacturing Process Types : 1) Hydro process (Wet process) 2) Pyro process (Dry process) Considering life cycle of cement, it undergoes various chemical and

Cement Production PowerPoint PPT Presentation

The PowerPoint PPT presentation: "Cement Production" is the property of its rightful owner Do you have PowerPoint slides to share? If so, share your PPT presentation slides online with PowerShow

标记:CementProductionWet Process of Cement Manufacturing: Detailed Overview

4 天之前 This article provides a comprehensive guide to the wet process, including its key steps, chemical reactions, advantages, and disadvantages What is the Wet Process of Cement

标记:CementManufacturing(PDF) THE CEMENT MANUFACTURING PROCESS

This abstract provides a concise overview of the cement manufacturing process and its environmental implications The cement manufacturing process involves the extraction and processing of raw materials, such as limestone, clay, and

标记:Cement Mill ProcessDry Process of Cement ManufacturingConcrete and CementCement Plant: The Manufacturing Process 4 5 World

2019年10月23日 Cement Plant: The Manufacturing Process worldcementassociation 1 Limestone (CaCO3) is taken from a quarry 2 4 3 The limestone is fed into a crusher and then

标记:ManufacturingCement Mill ProcessCement manufacturing process PPT Free

2016年1月29日 The raw material and clinker burning steps can be wet or dry processes The dry process dries and heats materials directly while the wet process adds water Portland cement is the most common type and is made

Wet Process Of Cement Manufacturing With

2 天之前 As the perflow diagram of the wet process of cement manufacturing, the rotary kiln is an essential and important component of a cement manufacturing factory 6 It is made of a thick steel cylinder of diameter

Manufacture process of cement PPT SlideShare

2017年10月8日 9 The burning process is carried out in the rotary kiln while the raw materials are rotated at 12rpm at its longitudinal axis The rotary kiln is made up of steel tubes having the diameter of 2530 meter and the length differs

Manufacturing of portland cement PPT Free Download

2016年7月31日 3 PROCESS OF MANUFACTURING OF CEMENT • The process of manufacturing of cement consists of grinding the raw materials , mixing them intimately in certain propor tions depending upon their purity and composition and burning them in a kiln at a temperature of about 1300 to 1500 C , at which temperature clinkers are formed and they are

PPT Engineering Materials Cement PowerPoint

2019年10月23日 Engineering Materials Cement Contents Introduction Classification of cements Portland Cement Raw materials of Portland cement Cement Manufacturing Process Flow chart of Portland Cement manufacturing process Cement Manufacturing Video Mixing and Crushing Dry Process Wet Process Slideshow

Cement Manufacturing cdnwordpresswebspeccloud

2024年1月15日 Cement Manufacturing Process Cement Manufacturing Process Cement Manufacturing Process CaO SiO 2 Al 2 O 3 Fe 2 O 3 MgO Loss Limestone (chalk) 520 57 08 03 04 404 Highsilica limestone 336 368 18 06

PPT – What is the manufacturing process of Portland cement

The process used by cement manufacturing companies in india consists of grinding the raw materials , mixing them intimately in certain proportions depending upon their purity and composition and burning them in a kiln at a temperature of about 1300 to 1500 C, at which temperature clinkers are formed and they are made into fine powder in addition with 3 to 5% of

1 Manufacturing Process of Cement Indus University

2020年8月13日 5 CEMENT –HISTORY In India, Portland cement was first manufactured in 1904 near Madras, by the South India Industrial LtdBut this venture failed Between 1912 and 1913, the Indian Cement Co Ltd, was established at Porbander (Gujarat) and by 1914 this Company was able to deliver about1000 tons of Portland cement By 1918 three factories were established

wet process of cement PPT SlideShare

2018年10月30日 Manufacturing of cement: The process of manufacture of cement consists of grinding the raw materials, mixing them intimately of certain proportions depending upon their purity and composition and burning them in a kiln at a temperature of about 1300 to 1500 ˚C, at which temperature, the material sinters and partially fuses to form nodular

Cement Manufacturing Process: Know Extraction, Processing

2024年9月10日 Manufacturing of Cement by Wet Process Wet process is an old Cement manufacturing process that has, in recent times, been replaced by the more energyefficient Dry process However, it is still used in some countries where the availability of raw materials and economic factors make it favorable Here is a stepbystep procedure for the wet

Life Cycle Assessment of Portland Cement

2022年6月13日 Cement Manufacturing Process Types : 1) Hydro process (Wet process) 2) Pyro process (Dry process) Considering life cycle of cement, it undergoes various chemical and physical transformations Considering product system: Inputs: Raw materials and energy (Electricity and fuel sources) Outputs: Principal product, Emissions to air, solid

Cement manufacturing process PPT SlideShare

2016年7月8日 Cement manufacturing process Download as a PDF or view online for free 26 likes • 4,133 views Rohan Sharma Follow The presentation contains detailed description about the manufacturing process of cement

Manufacturing process of concrete (for civil

2018年2月11日 Curing of concrete Curing is the process in which the concrete keeps its moisture for certain time period to complete hydration process Curing should be done properly to increase the strength of concrete Cement requires

Cement manufacturing process PPT Free Download

2015年11月25日 Evolution of the cement Process • Wet process easiest to control chemistry better for moist raw materials • Wet process high fuel requirements fuel needed to evaporate 30+% slurry water • Dry process kilns less fuel requirements • Preheater/Precalciner further enhance fuel efficiency allow for high production rates

All about the Wet Process of Cement Manufacturing

Applications of Wet Process Cement Manufacturing Wet process cement manufacturing method can be used to produce various types of Portland cement, such as ordinary Portland cement, white Portland cement, oil well cement, etc It can help your cement plant to achieve high quality and high output cement production

StepbyStep Guide to the Manufacturing of Cement

This method is advantageous due to its lower fuel consumption and reduced time of processing, making it a costeffective and efficient method in cement production Wet Process Conversely, the wet process involves mixing the crushed raw materials with

Manufacturing of concrete PPT SlideShare

2016年4月30日 Compaction of concrete Compaction of concrete is process adopted for expelling the entrapped air from the concrete In the process of mixing , transporting and placing of concrete air is likely to get entrapped in the concrete It has been found from the experimental studies that 1% air in the concrete approximately reduces the strength by 6%

Cement Manufacturing 1 PDF Cement Concrete

2023年5月12日 The document discusses the history and manufacturing process of cement It describes how ancient Egyptians and Romans used early forms of cement made from lime and pozzolana The modern dry process is then outlined, involving quarrying, crushing, grinding, heating materials in a kiln to form clinker, cooling, and grinding to produce cement The wet

Methods, Processes and Equipment Involved in Manufacturing Cement

2022年5月24日 5 Methods, Processes and Equipment Involved in Manufacturing Cement Free download as Powerpoint Presentation (ppt / pptx), PDF File (pdf), Text File (txt) or view presentation slides online

Manufacturing of cement PPT Free Download SlideShare

2018年1月1日 MANUFACTURING OF CEMENT Cement is the basic ingredient of constuction and the most widely used constructing material It is a very critical ingredient because only cement has the capicity to enhance the viscosity in concrete This viscocity provides an interlocking platform for all aggregates,water and admixtures

Wet Process vs Dry Process Cement LUTON

5 天之前 The water content of the slurry is usullly between 32% and 36% There is also a process, known as semiwet process, by which the raw material slurry can be dehydrated into raw material blocks and put into the kiln to calcine

Cement Plant: The Manufacturing Process 4 5 World

2019年10月23日 Cement Plant: The Manufacturing Process worldcementassociation 1 Limestone (CaCO3) is taken from a quarry 2 4 3 The limestone is fed into a crusher and then stored until needed The clinker is mixed with additives, such as gypsum, and then ground in a cement mill, which creates cement The cement is then packed and distributed to consumers

2 Types of Manufacturing of Cement Wet and

The slurry is introduced into a rotary kiln, a lengthy cylindrical boiler that rotates on its axis The kiln consists of three zones: the upper zone, known as the preheating zone, where hot gases from the lower zone dry and heat the slurry;

Production of concrete PPT Free Download SlideShare

2017年4月9日 3 Batching: Batching is the process of measuring concrete mix ingredients by either mass or volume and introducing them into the mixer To produce concrete of uniform quality, the ingredients must be measured accurately for each batch Volume batching Weight batching Volume batching: • This method is generally adopted for small jobs

Manufacturing of Cement By Dry and Wet Process Expert

Burning: In this operation, the slurry is directly fed into a long inclined steel cylinder called a Rotary kilnIn this kiln there are 3 different zones shown in fig below Cement Manufacturing Process Flow Chart (i) Drying Zones: In the wet process, the drying zone is comparatively larger than the dry process It is because the raw material in slurry form is directly fed into the kiln

CEMENT MANUFACTURING PROCESS ! TYPES OF CEMENT,

2024年5月14日 Cement manufacturing process is a reliable bonding material It is obtained by burning calcareous material (lime) and argillaceous material (clay) and then grinding, types of cement The cement manufacturing process was first produced by Joseph Aspidin, a mason from England As its color resembled a variety of sandstone found in Portland, he named it Portland

Manufacture of cement Classification and hydration PPT

2018年2月27日 2 Contents • Introduction • Classification of cements • Portland Cement • Raw materials of Portland cement • Cement Manufacturing Process • Flow chart of Portland Cement manufacturing process • Cement Manufacturing Video • Mixing and Crushing • Dry Process • Wet Process • Burning Process • View of complete setup • Rotary Klin zones • Chemical Reactions

Cement Manufacturing Process Chemical Engineering World

2020年9月26日 Cement Manufacturing Process Cement Manufacturing Process Cement Manufacturing Process Cement is a material which is used to bind other materials together Binding means it has an effect of gluing the substances together due to cohesive and adhesive action and then hardens and sets in order to become permanent Cement is usually not used

Process of manufacture of concrete PPT Free Download

2014年11月8日 3 BATCHING Batching is the process of measuring concrete mix ingredients by either mass or volume and introducing them into the mixer To produce concrete of uniform quality, the ingredients must be measured accurately for each batch Volume batching Weight batching Volume batching • This method is generally adopted for small jobs

Cement manufacturing applied chemistry PPT SlideShare

2017年4月19日 Cement manufacturing applied chemistry Download as a PDF or view online for free Submit • Download as PPT, PDF Wet process: In this process, the raw materials are changed to powdered form in the presence of water In this process, raw materials are pulverized by using a Ball mill, which is a rotary steel cylinder with

Cement manufacturing process PPT Free

2016年1月29日 The raw material and clinker burning steps can be wet or dry processes The dry process dries and heats materials directly while the wet process adds water Portland cement is the most common type and is made

Wet Process Of Cement Manufacturing With

2 天之前 As the perflow diagram of the wet process of cement manufacturing, the rotary kiln is an essential and important component of a cement manufacturing factory 6 It is made of a thick steel cylinder of diameter

Manufacture process of cement PPT SlideShare

2017年10月8日 9 The burning process is carried out in the rotary kiln while the raw materials are rotated at 12rpm at its longitudinal axis The rotary kiln is made up of steel tubes having the diameter of 2530 meter and the length differs

Manufacturing of portland cement PPT Free Download

2016年7月31日 3 PROCESS OF MANUFACTURING OF CEMENT • The process of manufacturing of cement consists of grinding the raw materials , mixing them intimately in certain propor tions depending upon their purity and composition and burning them in a kiln at a temperature of about 1300 to 1500 C , at which temperature clinkers are formed and they are

PPT Engineering Materials Cement PowerPoint

2019年10月23日 Engineering Materials Cement Contents Introduction Classification of cements Portland Cement Raw materials of Portland cement Cement Manufacturing Process Flow chart of Portland Cement manufacturing process Cement Manufacturing Video Mixing and Crushing Dry Process Wet Process Slideshow

Cement Manufacturing cdnwordpresswebspeccloud

2024年1月15日 Cement Manufacturing Process Cement Manufacturing Process Cement Manufacturing Process CaO SiO 2 Al 2 O 3 Fe 2 O 3 MgO Loss Limestone (chalk) 520 57 08 03 04 404 Highsilica limestone 336 368 18 06

PPT – What is the manufacturing process of Portland cement

The process used by cement manufacturing companies in india consists of grinding the raw materials , mixing them intimately in certain proportions depending upon their purity and composition and burning them in a kiln at a temperature of about 1300 to 1500 C, at which temperature clinkers are formed and they are made into fine powder in addition with 3 to 5% of

1 Manufacturing Process of Cement Indus University

2020年8月13日 5 CEMENT –HISTORY In India, Portland cement was first manufactured in 1904 near Madras, by the South India Industrial LtdBut this venture failed Between 1912 and 1913, the Indian Cement Co Ltd, was established at Porbander (Gujarat) and by 1914 this Company was able to deliver about1000 tons of Portland cement By 1918 three factories were established

wet process of cement PPT SlideShare

2018年10月30日 Manufacturing of cement: The process of manufacture of cement consists of grinding the raw materials, mixing them intimately of certain proportions depending upon their purity and composition and burning them in a kiln at a temperature of about 1300 to 1500 ˚C, at which temperature, the material sinters and partially fuses to form nodular

Cement Manufacturing Process: Know Extraction, Processing

2024年9月10日 Manufacturing of Cement by Wet Process Wet process is an old Cement manufacturing process that has, in recent times, been replaced by the more energyefficient Dry process However, it is still used in some countries where the availability of raw materials and economic factors make it favorable Here is a stepbystep procedure for the wet

应用于陶瓷生产的辊式磨的型号

--浙江研磨碳酸钙超细立磨解决方案

--重钙磨粉机雷蒙机600×9000

--即墨矿石粉碎机

--cfb脱硫工艺

--矿石磨粉机磨辊ssc00300406

--雷蒙磨矿石磨粉机安全操作规程

--重钙磨粉机雷蒙机筛网

--菱镁矿制粉设备厂家

--和平区浸出渣立磨客户案例

--石头开采需要去省里办理证件吗

--莫来石磨粉设备投资成本

--加工碳酸钙矿石的设备

--高岭土磨粉机制作机械

--广东碳酸盐矿石超细立磨生产厂家

--朝阳石英石

--浙江衢州重质碳酸钙立式辊磨机生产厂家

--生产一吨石灰粉要耗用多少石灰石

--开采白泥

--江西吉安白云石微粉磨项目现场

--黎明重工页岩粉碎

--江西江恒制粉加工设备制造厂

--铁无烟煤石灰石粉碎机

--TRM32.4型立磨

--欧版磨粉机DCF

--弋阳 高岭土

--上海高细立磨生石灰网

--辽宁鞍山滑石粉设备雷蒙磨

--玻璃废弃砖瓦专用石灰石碳酸钙磨粉机

--汉白玉与电石泥磨粉机那个更硬

--