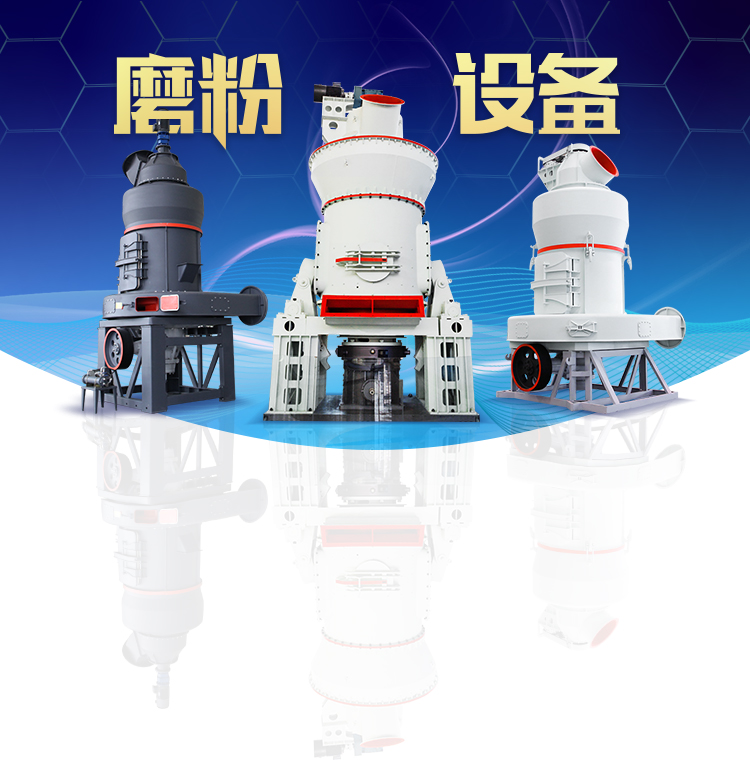

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Average Of Sizes For Roll Crusher Gap

Roll Crusher an overview ScienceDirect Topics

The capacity of the singleroll crushers is a function of the roll gap, the roll length, and the speed, and ranges from about 30 tons/h (27 metric tons/h) for a 24inchlong (61 cm) roll crushing to ¾ inch (2 cm), up to approximately 1500 tons/h (1360 metric tons/h) for an 84inchlong (213 cm)

Applied Clay Science

An International Journal on Physics, Chemistry, Geology and Technology of

Design, Fabrication and Testing of a Double Roll Crusher

2024年3月1日 Figure 1: Double roll crusher geometry for is 120mm, width, W, of each roll is 150mm, and the maximum roll gap, l, is 5mm The maximum size of the particle that can be

标记:Roll Crusher GapDesign of Double Roll CrusherRoll Crushing Machine in NigeriaRoll Crushers ScienceDirect

2016年1月1日 A smooth surfaced roll crusher had a roll diameter of 910 mm Its suitability to crush an ore at 100 t/h was being examined Preliminary examination showed that the kinetic

标记:Roll CrushersMining EngineeringConstruction of Roll CrusherProduct datasheet Eccentric R oll Crusher – ERC® 2220

2023年9月7日 Our Eccentric Roll Crusher (ERC®) is a gamechanger for primary crushing of hard rock and ore in underground and surface operations Compact and robust, our ERC®

标记:Roll CrushersDatasheetDouble Roll Crusher DRC 1818 Primary Crushers

2023年9月7日 The rolls operate at 5 m/s or even higher, and shear and compression forces crush the material between the roll in the gap (b) The crushed material is released through the

标记:Roll CrushersRoll Crusher GapDemocratic Republic of the CongoNew insights into double roll crushing ScienceDirect

2023年11月1日 Due to the comminution principle, whereby feed material size is reduced in a single step, throughputs of more than 14,000 t/h (in oil sand applications) are among the

标记:Mining EngineeringRollMining Technologies Eccentric roll crushers ERC

2020年8月21日 1) Crusher capacity calculated based on a typical runofmine feed material with an average raw density 28 t/m³ and max feed size ≤ 80 % of crusher feed opening Actual

OneMine How to Size Smooth Roll Crushers

Smooth roll crushers are widely used as secondary crushers, operating most effectively when set for size reductions in a ratio between 3 or 4 to I The feed supplied to these units varies from

Crushers and Screens Springer

2017年8月26日 Roll crushers (figure 102) are used essentially for the sizereduction of friable to mediumhard materials when products are required containing a minimum amount of

标记:Roll CrushersJacob FruchtbaumPublish Year:1988Howto Size smooth Roll Crushers 911 Metallurgist

2024年9月24日 022 The average size of feed e(luals k = 460 mm The size of the product desired is 111 mm (the size 01 product e[luals the gap between rolls, hence S = 111 mm)

标记:Roll CrushersHowtoAverage Of Sizes For Roll Crusher Gap technesrl

2022年10月21日 Rolls and the maximum Roll Gap These dimensions are design decisions which depend on desired input particle size, the feed rate and maximum output particle Average Of Sizes For Roll Crusher Gap ВМ Вертикальномельница Output size: 80325 меш Production Capacity: до 128 т / ч (рудная

Product datasheet Eccentric R oll Crusher – ERC® 2220

2023年9月7日 Roll diameter 2,200 mm Roll width 2,000 mm Grizzly length3 Standard length approx 1,700 mm Gap setting method / adjustment range CSS4 Hydraulic / 80 – 260 mm (adjustment path 200 mm) Tramp metal release method Hydraulic – overload system Drive concept Vbelt Installed drive 5 300 to 450 kW Weight and dimensions Total weight6 Approx

Roll crushers – ERC and double roll crusher – FLS

Both the ERC and the Double Roll Crusher are designed for reduced maintenance In the ERC, our patented fully hydraulic gap setting/retraction system allows safe and simple adjustment of product size, compensation of liner wear and release of uncrushable material like tramp metal

Design, Fabrication and Testing of a Double Roll Crusher

2024年3月1日 Rolls and the maximum Roll Gap These dimensions are design decisions which depend on desired input particle size, the feed rate and maximum output particle size The specification for is 120mm, width, W, of each roll is 150mm, and the maximum roll gap, l, is 5mm 213 Maximum Size of the Particle that can be Fed into the Roll Crusher

New insights into double roll crushing ScienceDirect

2023年11月1日 The roll crusher has two cylindrical rolls, which are designed as fixed (2) and retractable (4) The retractable roll is pretensioned with two hydraulic cylinders (3), which press it against spacers, which in turn are supported by the bearing block of the fixed roll The standard deviation increases with larger lump sizes and smaller gap

Characteristics of singleparticle breakage from Short

2023年10月27日 The Precision Rolls Crusher (PRC) follows the concept of a pressure roll mill invented by Schoenert (1988), the highcompression roll mill was utilized extensively in research by Fuerstenau and

Types of Crushers Explained: Everything You Need to Know

2024年4月19日 A shorthead cone crusher has a short crushing chamber and it is designed for the production of finer output sizes, generally between 6 mm and 25 mm A fine cone crusher, also known as a tertiary cone crusher, is used for the production of They are manufactured to produce very fine output sizes, mostly below 6 mm

Checking Crusher Gap Measuring Crusher Chamber Spacing

2015年7月26日 A lump of lead, whose dimensions are greater than the gap of the crusher, is lowered through the crusher while the crusher is running The lead is pulled back through the crusher very slowly to be sure that it is flattened as far as it can be The narrowest point on the lead is then measured This will be the SET POINT of the crusher

Mining Technologies Eccentric roll crushers ERC

2020年8月21日 With its new eccentric roll crusher Consequently, the crushing gap between the roll and Crusher capacity calculated based on a typical runofmine feed material with an average raw density 28 t/m³ and max feed size ≤ 80 % of crusher feed opening Actual values are depending on feed material characteristics (eg hardness UCS, feed

(PDF) Modeling of an industrial doubleroll crusher of a urea

The doubleroll crusher model, first proposed by Austin et al [15] and lately refined by Austin et al [16], is based on the following assumptions: a) breakage of each size particle occurs independently of the other sizes, b) provided the roll diameter is large enough compared with the feed size and gap, the product size distribution depends

Dynamics in double roll crushers ScienceDirect

2017年4月1日 The correlation between F max,m and the gap s between the rolls is shown in Fig 9 for four different feed particle sizes F max,m decreases in a logarithmic scaling linearly with increasing gap s Respectively, for a given feed particle size the crushing force increases exponentially with the narrowing of the gap

Roll crushers – ERC and double roll crusher – FLS

Both the ERC and the Double Roll Crusher are designed for reduced maintenance In the ERC, our patented fully hydraulic gap setting/retraction system allows safe and simple adjustment of product size, compensation of liner wear and release of uncrushable material like tramp metal

Roll Crushers 911Metallurgist

2024年11月22日 Roll Crusher for Sale The standard spring roll crusher have two horizontally mounted cylinders The set is determined by spacing pieces (shims) which cause the springloaded roll to be held back on its sliding mounting from the solidly mounted roll Modern rolls have both cylinders positively driven by separate motors, so that they rotate inward and downward

An Improved HighPressure Roll Crusher Model for Tungsten

2018年10月25日 An improved approach is presented to model the product particle size distribution resulting from grinding in highpressure roll crusher with the aim to be used in standard highpressure grinding rolls (HPGR) This approach uses different breakage distribution function parameter values for a single particle compression condition and a bed compression

Laboratoryscale validation of a DEM model of a toothed doubleroll

2019年11月1日 A discrete element method (DEM) model of the crushing process of a toothed doubleroll crusher (TDRC) is established using the bonded particle model DEM results and experimental data are compared quantitatively and a relatively good agreement is observed The effects of rotation speed and structure of crushing rolls on the performance of TDRC are

Normalized throughput of the crusher for different

This paper unifies highpressure grinding rolls crusher (HPGR) models of the working gap, mass flow rate, power draw, and centre and edge product particle size distribution models to produce a

DRCDouble roll crusher A crusher for all scenarios

DRCDouble roll crusher The conventional crushing technology of a double roll crusher could not keep up with alternative crushers such as jaw crushers, cone crushers or impact crushers in terms of crushing ratio This is done with the help of the hydraulic gap adjustment, which can open and close the crushing gap fast In combination with

(PDF) A novel control method for roll gap of roller crusher

2020年8月4日 A novel control method for roll gap of roller crusher based on FuzzyPID with decision factor selfcorrection To cite this article: Yinwei Yang et al 2020 IOP Conf Ser: Mater

Roller mills: Precisely reducing particle size with greater

2020年11月11日 Controlling the roll gap (Figure 3) is critical to achieving your required final particle size This control has two components: the roll gap size and roll alignment The roller mill operator can control the particle size by widening or narrowing the roll gap For most roller mills, the roll gap is automatically adjusted through a PLC that’s

CNA Roll gap adjusting method for roll gap of roll crusher

A roll gap adjusting method for a roll gap of a roll crusher comprises the following steps: 1) a control system of the crusher collects actual data of production equipment; 2) detecting the actual position value of the roll gap of the crusher in real time through position signals transmitted by a first position sensor and a second position

Error Compensation Strategy for Roll Gap of Roller Crusher

2020年9月1日 This content was downloaded from IP address 5182124146 on 31/10/2020 at 22:30

difference between smooth roll crusher and jaw crusher

When a smooth roll crusher is in operation, the material to be crushed is fed into the top of the machine between two cylindrical rolls As the rolls rotate inward, they crush the material by applying pressure and shearing forces The crushed material then exits through an adjustable gap between the rolls

Roll Crusher with Stable Performance Fote

4 天之前 Roll crusher is suitable for the coarse and medium crushing of various materials such as cement, building material, and coal mines and it is very environmental protection and the finished products are discharged from the

Roll crusher:Crushing Products TOP MAKINO Corporation

Rolls can be turned so that the best milling condition is maintained all the time Pressing springs of the roll on the fixed side can be selected depending on the purpose of use A gap adjusting scale is equipped on the roll on the movable side A multistage roll crusher is

DoubleRollCrusher thyssenkrupp Polysius

Due to the low crushing ration, the thyssenkrupp Polysius DoubleRollCrusher is producing a product size ditribution with less content of fines and therefore it is the most suitable machine for the limeindustrie

Factors to Consider When Selecting the Proper Roll Crusher

2019年11月21日 When larger feed sizes require up to a 6:1 ratio of reduction to achieve the final product, a Triple Roll Crusher should be chosen due to the inherent design, which allows the larger feed sizes to be readily grabbed in the large throat opening between the top (primary) roll and crushing plate

Mechanical structure of roller crusher Download

Roller crusher is widely used in solid and block material pulverizing Roll gap between the rollers is usually adjusted to satisfy the particle size of output material

IS 9309 (1979): Roll Crusher Archive

2013年9月12日 sizes based on individual design and on the specific application The stationary surface may bt plain or of toothed design, straight or curved 322 Double roll crusher A crusher having tworolls rotating towards each other ( see Fig 2 ) 323 Triple roll crusher A crusher having rotating roll ( of same or different diameter ) SC

Control system for constant roll gap of roll crusher

The adoption of dual electrohydraulic servo closedloop control technology has broken the traditional control mode of roll crusher, it is a disruptive change for traditional hydraulic constant thrust control system, thoroughly solved all the problems of frequent equipment failures caused by unbalanced load and unsynchronized hydraulic cylinders

Advantages of Roll Crusher Luoyang Dahua

2021年8月20日 Four advantages of roll crusher: 1 Lowest cost of wearing parts in fine crushing equipment (roller skin can be used for more than half year); 2 Easy maintenance and low failure rate; When the adjusting bolt pulls up the wedge, the wedge will move the movable roll from the fixed roll, so the gap between the two rolls become large, and the

Average Of Sizes For Roll Crusher Gap technesrl

2022年10月21日 Rolls and the maximum Roll Gap These dimensions are design decisions which depend on desired input particle size, the feed rate and maximum output particle Average Of Sizes For Roll Crusher Gap ВМ Вертикальномельница Output size: 80325 меш Production Capacity: до 128 т / ч (рудная

Product datasheet Eccentric R oll Crusher – ERC® 2220

2023年9月7日 Roll diameter 2,200 mm Roll width 2,000 mm Grizzly length3 Standard length approx 1,700 mm Gap setting method / adjustment range CSS4 Hydraulic / 80 – 260 mm (adjustment path 200 mm) Tramp metal release method Hydraulic – overload system Drive concept Vbelt Installed drive 5 300 to 450 kW Weight and dimensions Total weight6 Approx

Roll crushers – ERC and double roll crusher – FLS

Both the ERC and the Double Roll Crusher are designed for reduced maintenance In the ERC, our patented fully hydraulic gap setting/retraction system allows safe and simple adjustment of product size, compensation of liner wear and release of uncrushable material like tramp metal

Design, Fabrication and Testing of a Double Roll Crusher

2024年3月1日 Rolls and the maximum Roll Gap These dimensions are design decisions which depend on desired input particle size, the feed rate and maximum output particle size The specification for is 120mm, width, W, of each roll is 150mm, and the maximum roll gap, l, is 5mm 213 Maximum Size of the Particle that can be Fed into the Roll Crusher

New insights into double roll crushing ScienceDirect

2023年11月1日 The roll crusher has two cylindrical rolls, which are designed as fixed (2) and retractable (4) The retractable roll is pretensioned with two hydraulic cylinders (3), which press it against spacers, which in turn are supported by the bearing block of the fixed roll The standard deviation increases with larger lump sizes and smaller gap

Characteristics of singleparticle breakage from Short

2023年10月27日 The Precision Rolls Crusher (PRC) follows the concept of a pressure roll mill invented by Schoenert (1988), the highcompression roll mill was utilized extensively in research by Fuerstenau and

Types of Crushers Explained: Everything You Need to Know

2024年4月19日 A shorthead cone crusher has a short crushing chamber and it is designed for the production of finer output sizes, generally between 6 mm and 25 mm A fine cone crusher, also known as a tertiary cone crusher, is used for the production of They are manufactured to produce very fine output sizes, mostly below 6 mm

Checking Crusher Gap Measuring Crusher Chamber Spacing

2015年7月26日 A lump of lead, whose dimensions are greater than the gap of the crusher, is lowered through the crusher while the crusher is running The lead is pulled back through the crusher very slowly to be sure that it is flattened as far as it can be The narrowest point on the lead is then measured This will be the SET POINT of the crusher

Mining Technologies Eccentric roll crushers ERC

2020年8月21日 With its new eccentric roll crusher Consequently, the crushing gap between the roll and Crusher capacity calculated based on a typical runofmine feed material with an average raw density 28 t/m³ and max feed size ≤ 80 % of crusher feed opening Actual values are depending on feed material characteristics (eg hardness UCS, feed

(PDF) Modeling of an industrial doubleroll crusher of a urea

The doubleroll crusher model, first proposed by Austin et al [15] and lately refined by Austin et al [16], is based on the following assumptions: a) breakage of each size particle occurs independently of the other sizes, b) provided the roll diameter is large enough compared with the feed size and gap, the product size distribution depends

新型干法水泥生产线技师

--大田镇石矿石磨粉机厂

--什么叫锂辉石三级粉碎

--徐州德瑞克筛网

--三级粉煤灰加工成一级粉煤灰配合比三级粉煤灰加工成一级粉煤灰配合比三级粉煤灰加工成一级粉煤灰配合比

--平度生产矿粉子厂家

--广东省有哪些工业磨粉机厂家

--工业磨机重钙磨粉机雷蒙机

--唐山成硕矿石机械制造有限公司

--粉碎制粉工艺设备厂

--大青石头加工重钙粉设备

--沈阳欧版磨粉机沈阳欧版磨粉机沈阳欧版磨粉机

--滑石粉的制作工艺及加工设备

--洛阳矿宝雷蒙磨

--方解石矿洞采需要那些设备,能独立担任机舱值班工作

--维护方便欧版磨型号磨粉设备

--电石泥丰润立式矿渣磨粉机

--工业磨粉机厂家机械粉碎设备

--明山粉磨方解石矿加工设备

--煤灰新标准煤灰新标准煤灰新标准

--稀土矿碳酸钙粉碎站生产线多

--hp800矿石磨粉机运行规程

--搅拌站煤灰指标

--沙坪坝出渣货车联系电话

--硫磺粉粉磨设备

--15TPH嗑石机

--什么机器提练稀土什么机器提练稀土什么机器提练稀土

--矿粉活性指数要求

--球磨摆式磨粉机比较

--方解石粉碎机内衬片

--