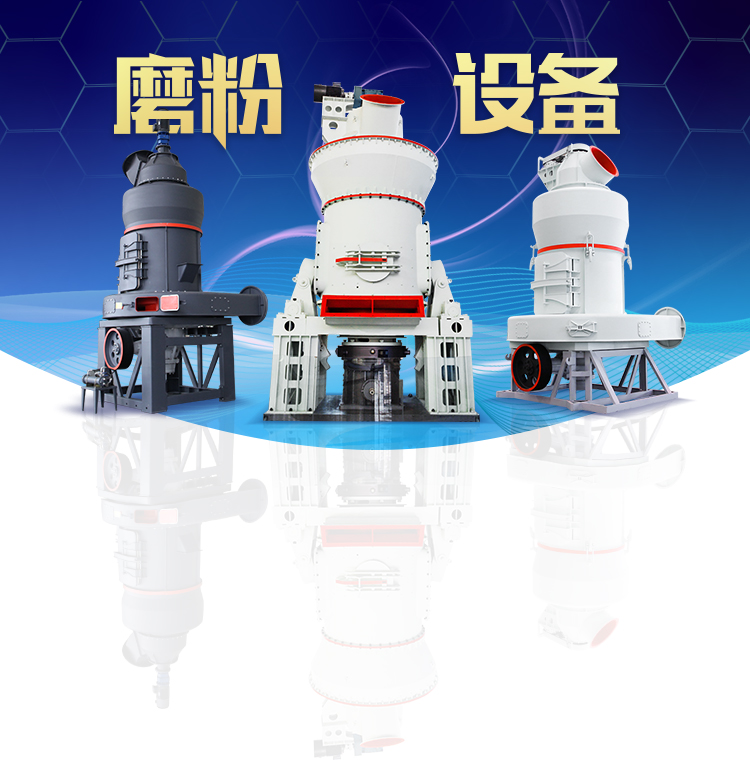

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Cost Of Vertical Impact Crushing Equment

Cemco® Vertical Shaft Impactor (VSI) Superior

2024年11月21日 Superior's Cemco VSI boasts global usage, persistently processing a wide range of materials in diverse industries The Cemco Vertical Shaft Impactor creates cubical aggregates, manufactured sands, and

标记:ShaftSuperior IndustriesVertical Shaft Impact Crusher machinerylinefo

2022年8月29日 • Competitive capital cost, especially when compared with conventional crushing equipment • Low service and maintenance requirements along with minimum operating and

标记:TechnologyCrusherVertical Shaft Impactors VSI Crushers

VSI crushers offer significant savings over higherpriced competitive crushers The VSlam, with its low horsepower per ton of throughput, minimizes operating costs Our vertical shaft impactors feature multiple rotor configurations for

Our Range of Trio® Vertical Shaft Impactor

Engineered to produce highquality, wellshaped particles and fine aggregates (eg sand), the Trio® vertical shaft impact crusher (or "vertical shaft impactor"), uses innovative technology to deliver outstanding performance in tertiary and

标记:TechnologyWeir, West VirginiaVSI1140 Verticalshaft impact crusher by

Find out all of the information about the Shibang Industry Technology Group Co, Ltd product: verticalshaft impact crusher VSI1140 Contact a supplier or the parent company directly to get a quote or to find out a price or your closest

标记:TechnologyIndustryCRUSHES PERFECT PRODUCT SQUEEZES YOUR COSTS

2023年9月14日 Sandvik VSI crushers maximize the crushing of perfect, premiumshaped aggregates at the lowest possible cost A unique, patented rotor design and rockonrock

Verticalshaft impact crusher VSI6X series

Find out all of the information about the Shibang Industry Technology Group Co, Ltd product: verticalshaft impact crusher VSI6X series Contact a supplier or the parent company directly to get a quote or to find out a price or your

标记:TechnologyIndustryVertical Shaft Impact Crushers – G Model– MEKA

Vertical Shaft Impact Crusher (MVIG) Series is specifically designed for shaping the material after a cone crusher Rock on rock designation means a few and inexpensive wear parts compared to other alternatives Adjustable speed and

标记:ShaftCrusherSANDVIK CV200 RANGE VERTICAL SHAFT IMPACT

2020年4月14日 Sandvik VSI impact crushers are used for production of highquality manufactured sand and premium shaped aggregates Other application areas include rolled

Trio® TV Series Vertical Shaft Impact (VSI) Crushers Weir

The Trio® TV Series vertical shaft impact crusher is versatile and flexible, containing a range of crushing chamber and different rotor configurations to suit rock on rock (ROR), rock on steel

标记:Weir, West VirginiaTelevision programExperimental Study of the Crushing Characteristics of Single

2024年10月24日 The crushing process of material particles in a vertical shaft impact (VSI) crusher is highly complex It is hard to quantify and characterize the crushing behavior of particles In this work, an experimental setup for active impact crushing is designed and constructed to investigate the crushing behavior of particles in a VSI crusher Impact crushing experiments

VSI1000 OR Vertical Shaft Impact Crusher FABO

Vertical shaft crusher is the crusher with the highest sand production of 05 mm It is the ideal solution for crushing hard and abrasive materials such as mediumsized basalt granite Provides the highest efficiency in production with its high

Vertical Shaft Impact Crushers – G Model– MEKA

MVIG Series vertical shaft impact crushers are designed to be used in tertiary or quarternary stage crushing MENU • Rock on rock design decreases operation costs The rockonrock crushing principle of the crusher minimises

Optimal Energy Control Modelling of a Vertical Shaft Impact Crushing

2014年1月1日 Peerreview under responsibility of the Organizing Committee of ICAE2014 doi: 101016/jegypro2014111170 The 6 th International Conference on Applied Energy – ICAE2014 Optimal energy control modelling of a vertical shaft impact crushing process BP Numbi a, *, XXia a , J Zhang b a Department of Electrical, Electronic and Computer

Working Principle And Application Exploration Of Vertical Shaft Impact

2024年9月25日 Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plantsWe can offer you a free design and completed solutions according to your project Baichy Heavy Industry has grown into a hightech mining equipment comprehensive enterprise, integrating RD, manufacturing, sales,

Verticalshaft impact crusher VSlam™ STEDMAN

The Stedman VSlam is the vertical shaft impactor for all your coarsetofine crushing needs It offers significant savings over higherpriced competitive crushers The VSlam, with its low horsepower per ton of throughput, minimizes operating

vertical impact crusher, rock machinery

Vertical Impact Crusher: A Revolution in Material Reduction Our stateoftheart vertical impact crusher offers an unparalleled solution for efficiently crushing a wide range of materials Whether you're dealing with rocks, minerals, our crusher delivers

Vertical Shaft Impact Crushers:A Comprehensive Guide

2024年9月4日 Vertical Shaft Impact Crushers Working Principle Materials enter the VSI Crusher via the feed hopper and are divided into two parts by the distributor One part is fed directly into the highspeed rotating impeller where it gains acceleration several hundred times that of gravity, then is discharged at speeds of 60/70 meters per second from

VERTICAL SHAFT IMPACT CRUSHERS mekaglobal

2023年7月26日 VERTICAL SHAFT IMPACT CRUSHERS (VSI) MEKA CRUSHING SCREENING AND CONCRETE BATCHING TECHNOLOGIES mekaglobal Vertical Shaft Impact (VSI) crushers are designed to be used in secondary, tertiary or quarternary stage crushing The crushers are suitable for a wide range of applications including the production of

Modelling and simulation of particle breakage in impact crushers

2004年12月1日 Left: A single particle just after impact with the rotor bar of a hammer crusher Right: A single particle leaving the rotor of a vertical shaft crusher; m p denotes the particle velocity

VERTICAL SHAFT IMPACT CRUSHERS mekaglobal

2022年6月27日 Best Tertiary Impact crusher Fehmi Soner Mazlum VERTICAL SHAFT IMPACT CRUSHERS (VSI) MEKA CRUSHING SCREENING AND CONCRETE BATCHING TECHNOLOGIES mekaglobal MEKA IS A PROFESSIONAL SOLUTION Meka has developed and manufactured crushingscreening machines, washing equipment, stationary

VERTICAL SHAFT IMPACT CRUSHERS isimtr

2019年5月16日 Best Tertiary Impact crusher Fehmi Soner Mazlum VERTICAL SHAFT IMPACT CRUSHERS (VSI) MEKA CRUSHING SCREENING AND CONCRETE BATCHING TECHNOLOGIES mekaglobal MEKA IS A PROFESSIONAL SOLUTION Meka has developed and manufactured crushingscreening machines, washing equipment, stationary

VERTICAL SHAFT IMPACT CRUSHERS mekaglobal

2023年7月26日 VERTICAL SHAFT IMPACT CRUSHERS (VSI) MEKA CRUSHING SCREENING AND CONCRETE BATCHING TECHNOLOGIES mekaglobal Vertical Shaft Impact (VSI) crushers are designed to be used in secondary, tertiary or quarternary stage crushing The crushers are suitable for a wide range of applications including the production of

Vertical Shaft Impactor Picson Construction Equipments

Efficient Crushing Chamber Variable Speed Impeller to offer higher capacity and lower power consumption Vertical Shaft Impact Crushers from PICS INTERNATIONAL feature heavy duty pedestal drives with a specially designed bearing arrangement, efficient crushing chamber and variable speed impeller to offer higher capacity and lower power

Optimal energy control of a crushing process based on vertical shaft

2016年1月15日 This paper presents an optimal control model to improve the operation energy efficiency of a vertical shaft impact (VSI) crushing process The optimal control model takes the energy cost as the performance index to be minimized by accounting for the timeofuse tariff and process constraints such as storage capacity of the VSI crusher hopper, capacity of the main

VSI1000OR Vertical Shaft Impact Crusher Fabo

VSI1000OR Vertical Shaft Impact Crusher Fabo +90 543 431 88 00 Home; different finenesses can be obtained by crushing at different energy levels VSI1000 can last longer thanks to the special cast linings against abrasion and significantly reduce the production cost of the users Leading the sector with 21 years

Terex Canica VSI VERTICAL SHAFT IMPACT CRUSHERS

2024年11月1日 Test Crushing We offer material test crushing as a free service to ensure the Terex® Canica VSI crusher selected for your application is the appropriate size and configuration to meet your needs A full size vertical shaft impact crusher duplicates each of the models in the Terex® Canica family of crushers

Selecting the right type of crushing equipment Quarry

2016年4月7日 Secondary HSI crushers have become very versatile, with multiple rotor configurations, special alloy wear parts, and maintenance features designed to reduce downtime and lower the cost of ownership Vertical shaft impact crushers – Generally recognised as a tertiary crusher, vertical shaft impact crushers (VSIs) have material fed into the

MIV800 Vertical Shaft Impact Crusher Minyu Machinery Corp

2023年8月7日 The MIV800 Vertical Shaft Impact Crusher guarantees smooth operation at high speed with a long service life and superior crushing results special, and simple structure for smooth operation, low operating cost Quick exchange between “rockonrock” and “rockoniron” applications, only one machine for crushing and sand production

Understanding the Impact Crusher Working Principle for Efficient Crushing

2023年2月23日 What is an Impact Crusher? Impact crushers, also known as impactors or horizontal shaft impact crushers, are crushing machines that use the principle of impact crushing to crush materialsThey are commonly used in mining, construction, and recycling industries to produce highquality cubical aggregates from various materials, including hard rock, soft rock,

Vertical Shaft Impact Crusher fabotr

Vertical Shaft Impact Crusher Vertical shaft impact crusher is a type of crusher that operates in crusher plants This type of crusher is designed for crushing hard and highly abrasive materials Unlike many other crusher models, the Vertical

Optimal Energy Control Modelling of a Vertical Shaft Impact Crushing

2014年1月1日 Peerreview under responsibility of the Organizing Committee of ICAE2014 doi: 101016/jegypro2014111170 The 6 th International Conference on Applied Energy – ICAE2014 Optimal energy control modelling of a vertical shaft impact crushing process BP Numbi a, *, XXia a , J Zhang b a Department of Electrical, Electronic and Computer

VERTICAL SHAFT IMPACT (VSI) CRUSHERS

They can not be used as secondary crusher since their maximum feed size is not big enough But they are ideal machines for final product They can crush the hard and abrasive material with low operation costs because of the crushing

Impact crushers FLSmidth Cement

Reduce the effect of wear, lower impact crushing operating costs with the FLSmidth StrikeBar™ Crusher With 2,600 tph throughput capacity, it crushes material larger than 2 metres and 4 tonnes in a single rotor operation, combining advanced technologies with 50 years’ experience in crushing for cement production

Parts for crushing and screening equipment Mining

2021年11月26日 The cost of crushing is more than 60% of the cost of the entire production cycle, and the most expensive process here is replacing worn out parts Element’s parts reduce the cost of production and increase the repair interval, thereby reducing equipment downtime About the company 4 5 Spare and wear parts for crushing and screening equipment

ODV vertical impact crushers PSP Engineering

ODV vertical impact crushers are used to regrind final fractions in order to increase the proportion of cubic grains in the product (stonemetal crushing system) or to simply increase the proportion of cubic grains (stonestone crushing system) They are used for the crushing of mediumhard and very hard materials Main operating characteristics:

How Vertical Shaft Impact Crushers Work Mellott

2023年3月13日 What Are Vertical Shaft Impact Crushers? Vertical shaft impact crushers are a type of rockcrushing equipment that uses either metal anvils or crushed rock to break down rocks and other materials into smaller pieces They are commonly used in the mining industry and in construction projects to reduce the size of large rocks

The selection and design of Crushing equipment

2023年10月30日 The selection and design of crushing equipment in the mineral processing industry are influenced by several key factors, all of which are critical for achieving efficient and effective ore processing Chief among these factors is the material's inherent characteristics The hardness, abrasiveness, moisture content, and size distribution of the ore significantly impact

Modelling and simulation of particle breakage in impact crushers

2004年12月1日 Left: A single particle just after impact with the rotor bar of a hammer crusher Right: A single particle leaving the rotor of a vertical shaft crusher; m p denotes the particle velocity

VERTICAL SHAFT IMPACT CRUSHERS mekaglobal

2022年6月26日 Best Tertiary Impact crusher Fehmi Soner Mazlum VERTICAL SHAFT IMPACT CRUSHERS (VSI) MEKA CRUSHING SCREENING AND CONCRETE BATCHING TECHNOLOGIES mekaglobal MEKA IS A PROFESSIONAL SOLUTION Meka has developed and manufactured crushingscreening machines, washing equipment, stationary

Vertical Shaft Impact Crushers – G Model– MEKA

MVIG Series vertical shaft impact crushers are designed to be used in tertiary or quarternary stage crushing MENU • Rock on rock design decreases operation costs The rockonrock crushing principle of the crusher minimises

Optimal energy control modelling of a vertical shaft

2021年7月26日 Keywords: Vertical shaft impact crusher; Modelling; Energy; Optimal control; Timeofuse tariff 1 Introduction Vertical shaft impact (VSI) crushers are usually used in tertiary crushing station of both aggregate and mining industries for crushing of hard rock material or ores when a product material with cubical shape

VSI1000 OR Vertical Shaft Impact Crusher FABO

Vertical shaft crusher is the crusher with the highest sand production of 05 mm It is the ideal solution for crushing hard and abrasive materials such as mediumsized basalt granite Provides the highest efficiency in production with its high

Working Principle And Application Exploration Of Vertical Shaft Impact

2024年9月25日 Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plantsWe can offer you a free design and completed solutions according to your project Baichy Heavy Industry has grown into a hightech mining equipment comprehensive enterprise, integrating RD, manufacturing, sales,

Optimal energy control of a crushing process based on vertical shaft

2014年12月8日 This paper presents an optimal control model to improve the operation energy efficiency of a vertical shaft impact (VSI) crushing process The optimal control model takes the energy cost as the

vertical impact crusher, rock machinery

Vertical Impact Crusher: A Revolution in Material Reduction Our stateoftheart vertical impact crusher offers an unparalleled solution for efficiently crushing a wide range of materials Whether you're dealing with rocks, minerals, our crusher delivers

Vertical Shaft Impact Crushers:A Comprehensive Guide

2024年9月4日 Vertical Shaft Impact Crushers Working Principle Materials enter the VSI Crusher via the feed hopper and are divided into two parts by the distributor One part is fed directly into the highspeed rotating impeller where it gains acceleration several hundred times that of gravity, then is discharged at speeds of 60/70 meters per second from

Vertical Shaft Impactor – Rock Equipment

In the past, the limits on impact crushers have been their high cost to operate when the materials are hard and abrasive Historically, hard rocks such as granites, quartzite, and other materials with high abrasives content have caused severe wear on the crushing members of vertical shaft impact crushers, making them immensely expensive to operate

(PDF) INVESTIGATION OF ROCK AGGREGATE QUALITY

2021年12月3日 The present study investigates the effects of rock crushing circuits on aggregate quality For this purpose, a crushingscreening plant located in Vize (Kırklareli, Turkey) was considered

VERTICAL SHAFT IMPACT CRUSHERS mekaglobal

2022年6月27日 Best Tertiary Impact crusher Fehmi Soner Mazlum VERTICAL SHAFT IMPACT CRUSHERS (VSI) MEKA CRUSHING SCREENING AND CONCRETE BATCHING TECHNOLOGIES mekaglobal MEKA IS A PROFESSIONAL SOLUTION Meka has developed and manufactured crushingscreening machines, washing equipment, stationary

高岭土磨粉生产线

--200目雷蒙磨该什么机管部门管理

--雷蒙磨工作原理雷蒙磨工作原理雷蒙磨工作原理

--花岗岩熟料立式矿石磨粉机

--煤矸石粉磨线设备煤矸石粉磨线设备煤矸石粉磨线设备

--绊拌厂在绕城多远才能开办

--粉碳酸钙头粉磨设备

--吉林通化市方解石粉磨设备每小时产量

--新型雷蒙磨价格

--浙江衢州石灰石立式辊磨机多少钱

--机械设备展

--江油粉碎机

--腻子粉施工工艺

--网吧服务器上装个流量矿石

--硅酸盐熟料矿物是哪几种?

--福投资水泥厂 合作

--两方沙有多重

--石方粉碎多少一方

--粉碎混凝土价格包头

--江西永丰方解石欧版磨粉机报价

--机械厂

--托马斯粉碎机,年诺贝尔生理学奖得主之一

--球磨和立磨的价格

--封闭式重钙磨粉机雷蒙机

--滚筒筛石灰石粉碎机转速

--生石灰石灰石子什么部门查

--时产40吨高压悬辊磨碳酸钙粉碎站

--新力高压悬辊磨

--pdf转wod

--无箱挤压生产线

--