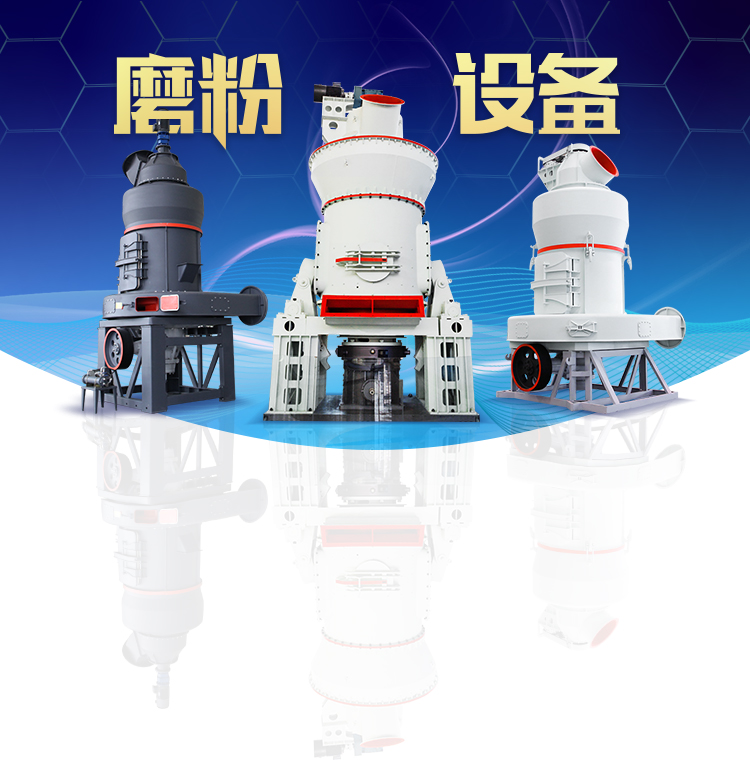

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Processing Iron Involved

Iron processing Definition, History, Steps, Uses, Facts

iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned Included in this article also is a discussion of the mining of iron and of its preparation for smelting Iron (Fe) is a relatively dense metal with a silvery white appearance and

Wrought Iron

wrought iron, one of the two forms in which iron is obtained by smelting; the other is

Iron Ore Processing: From Extraction to

2024年4月26日 Iron ore processing is a complex and vital process that transforms raw iron ore into usable steel From exploration and extraction to grinding, beneficiation, and ironmaking, each stage plays a crucial role in

标记:Iron Ore ProcessingIron Ore To Steel ProcessIron processing Smelting, Refining, Alloying

Iron processing Smelting, Refining, Alloying: The primary objective of iron making is to release iron from chemical combination with oxygen, and, since the blast furnace is much the most efficient process, it receives the most attention

标记:Iron MakingEncyclopaedia BritannicaThe Blast Furnace ProcessIron Ore Processing, General Springer

2022年10月19日 Making iron and steel from iron ore requires a long process of mining, crushing, separating, concentrating, mixing, agglomeration (sintering and pelletizing), and

标记:Iron Ore ProcessingIron Ore To Steel ProcessIron Ore Mining ProcessIron Ore Processing an overview ScienceDirect Topics

Iron ore processing refers to the techniques used to extract iron from oolitic iron ores, involving processes such as beneficiation, roasting, and magnetic separation to remove impurities like

标记:Iron Ore ProcessingIron Ore ProductionMining IndustryIron Ore Processing, General SpringerLink

2022年10月20日 Making iron and steel from iron ore requires a long process of mining, crushing, separating, concentrating, mixing, agglomeration (sintering and pelletizing), and

标记:Iron Ore ProcessingIron Ore To Steel ProcessIron Ore Mining ProcessIronmaking 101 – From Ore to Iron with

2017年10月17日 Direct iron reduction processes produce a form of sponge iron called direct reduced iron (DRI) Smelting reduction and direct iron reduction can reduce energy input, lower greenhouse gas emissions and minimize slag

标记:Iron Ore To Steel ProcessIron Ore Smelting ProcessCast IronIron processing Ores, Smelting, Refining

Iron ore sintering consists of heating a layer of fines until partial melting occurs and individual ore particles fuse together For this purpose, a travelinggrate machine is used, and the burning of fine coke (known as coke breeze) within

标记:Iron Ore ProductionEncyclopaedia BritannicaMining IndustryCrushed Iron OreThe four steps of iron working: 1 (extraction), 2

Download scientific diagram The four steps of iron working: 1 (extraction), 2 (smelting), 3 (primary smithing), and 4 (secondary smithing or forging) of the iron, with the involved raw

标记:SmeltingIronOperations and Basic Processes in Ironmaking

Divided into seven chapters, it discusses the following topics: raw materials for steel production (coking coal, iron ore, slagforming agents and fluxes, scrap, ferroalloys and prereduced materials), the sintering process (used to prepare

标记:Iron Ore To Steel ProcessIron Ore ProductionSpringer Science+Business MediaFull article: Iron ore processing Taylor Francis Online

2016年8月24日 This special issue of Mineral Processing and Extractive Metallurgy presents a selection of the best metallurgy papers delivered at the very successful international ‘Iron Ore 2015’ conference held at the Perth Convention and Exhibition Centre, Australia, on 10–12 July 2015 This was the seventh in the series of biennial conferences featuring recent

The four steps of iron working: 1 (extraction), 2

The four steps of iron working: 1 (extraction), 2 (smelting), 3 (primary smithing), and 4 (secondary smithing or forging) of the iron, with the involved raw materials and resulting products as

Iron Ore production in the Pilbara Rio Tinto

2023年6月2日 Activities involved in finding, mining and processing iron ore at our Pilbara operations have been simplified in the following diagram Rio Tinto operates 11 iron ore mines in the Pilbara and the specific sequence of activities varies from mine to mine Excellence in planning, scheduling and quality control are fundamental to the process

Process of steelmaking Tata Steel

2 天之前 When sufficient hot metal has formed at the bottom of the furnace, we drill open the furnace and tap the iron The hot metal is collected in torpedoshaped train waggons and is then ready for transport to the BOS (Basic Oxygen Steelmaking) plant next door The converter in the BOS Plant turns the pig iron into steel

How to process iron ore SANDMINE

2024年1月19日 The following is an introduction to the steps of iron ore processing: Pure magnetite can be directly put into the furnace to make iron, but after all, there are still more associated ores For some magnetite with relatively high impurity content, simple crushing and screening, grinding and magnetic separation are required to produce concentrate

A Visual Guide: Steel Making Process Chart Cabaro Group

2024年3月17日 The transformation of iron ore into steel is a remarkable process that involves a series of detailed steps Beginning with the extraction of iron ore from the earth through mining operations, this raw material is then treated and prepared for the smelting phase The extracted ore undergoes processes such as crushing, grinding, and concentration

Iron Ore Processing, General Springer

2022年10月19日 Making iron and steel from iron ore requires a long process of mining, crushing, separating, concentrating, mixing, agglomeration (sintering and pelletizing), and shipping to steel mills Iron ore processing is characterized by a constant adaptation to changing raw materials and market conditions It is the link between the mined

Iron Ore Processing an overview ScienceDirect Topics

The chronological distribution of the references cited in this paper is given in Fig 1 showing that the main reference material used in this review was published in the decade of the 1960s where there was significant research conducted in the United States on the processing of their iron ores The author is aware of significant publications in Portuguese (Brazilian iron ore industry), in

Ironmaking Process an overview ScienceDirect Topics

The HiQIP (HighQuality Iron Pebble) process is a granular ironmaking method developed by JFE Steel The process manufactures granular iron in an RHF The granular iron has a diameter of 20–40 mm and is shaped like the playing pieces called “stones” used in the Japanese board game of go The development of this process began in 1996 by

Guide to Modern Smelting Processes CED Engineering

2024年4月21日 Early iron smelting was accomplished using charcoal fueled furnaces known as bloomeries Iron's Impact: Iron tools and weapons were harder and more durable than bronze, leading to transformative changes in agriculture, construction, and warfare Iron was the foundation of empires like the Roman Empire, as it enabled the construction of

Top 6 Steps Of Iron Ore Processing Australian

2023年9月18日 To know more about this process and iron ore mining, contact us and learn all about iron ore, polyurethane, and the associated processes of processing iron ore Stockpiling And Crushing Before being crushed, the iron

Rusting of Iron: Explanation, Chemical Reaction,

2023年7月15日 Chemistry of Iron Rusting Rust formation is a chemical process that takes place when iron, or an iron alloy, is exposed to Oxygen (O) in the presence of moisture The observed reaction does not exhibit an

Life cycle assessment of iron ore mining and processing

2015年1月1日 The estimated GHG emissions were 119 kg CO 2 e for mining and processing 1 t of iron ore The embodied energy values were 153 MJ/t ore for iron ore The results showed that loading and hauling made the largest contributions (approximately 50%) to the total GHG emissions from the mining and processing of iron ore

Iron and SteelMaking Process SpringerLink

2020年6月10日 Despite formation of Fe, there are several other processes are involved to complete the ironmaking process Most predominate transformations including MnO to Mn, SiO 2 to Si, removal of sulphur, P 2 O 5 to P and slag formation are noticed 2251 Reduction of MnO It is a multistage process occurring in the blast furnace stack region

How Iron Is Made Steel Museum

To convert iron ore into metallic iron, oxygen and impurities must be removedThis process requires heat and a reducing agent, a substance that combines with the oxygen and releases it from the ore In the blast furnace process, iron ore, coke (processed coal), and limestone (the charge) are poured into a vessel lined with refractory (heatresistant brick)

Iron Ore Pelletizing Process: An Overview IntechOpen

The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking This chapter shows the status of the

Steel Manufacturing: Process, Types, and Standards

2024年5月13日 The Steel Manufacturing Process The steel production process is a multifaceted journey that begins with extracting and processing iron ore, a primary raw material essential to steel making Iron ore undergoes a series of refining steps to extract the iron content, culminating in the creation of molten iron

Iron ore beneficiation: an overview ScienceDirect

2023年1月1日 Special focus has been given on the selection of beneficiation processes routes based on mineralogy for processing of lowgrade iron ore, various steps involved in the test work along with the commonly used equipment in a commercial set up A final recommended and operating process flowsheet for an iron ore deposit is also provided Moreover

Revolutionising iron ore processing Australian Mining

2023年10月2日 W ith a legacy rooted in Australian iron ore processing since the 1950s, Derrick Corporation continues to reshape the industry with cuttingedge solutions

Steel Production Process: The Comprehensive Guide

2023年9月1日 Ever wondered how steel, a cornerstone of modern civilization, is made? This comprehensive guide dives into the intricate steel production process, from raw materials to finished products Discover how elements like carbon, manganese, and silicon shape steel’s properties, and learn about the crucial steps involved, including smelting, rolling, and refining

233: Metallurgy of Iron and Steel Chemistry

Cast iron has already been mentioned above This section deals with the types of iron and steel which are produced as a result of the steelmaking process Wrought iron: If all the carbon is removed from the iron to give high purity iron,

Blast Furnace Process Steel Museum

Molten iron is produced in a blast furnace by the following steps: 1 Charge (solid iron ore, coke, and limestone) is constantly dumped into the top of the furnace 2 A blast of hot air is blown into the furnace from the bottom 3 Coke is the fuel

Hazard Identification, Risk Assessment, and

2017年5月1日 The hazards of the process involved in different activities The various steps of occupational health assessment of hazardous process in an iron ore pelletizing industry are as follows: Process description The concentrate

Extraction of Iron from Hematite Cambridge O Level

2023年11月2日 The symbol equations for the different stages of the extraction of iron from hematite are: Zone 1: The burning of carbon (coke) to provide heat and produce carbon dioxide:; C (s) + O 2 (g) → CO 2 (g) Zone 2: The reduction of carbon dioxide to carbon monoxide:; CO 2 (g) + C (s) → 2CO (g) Zone 3: The reduction of iron(III) oxide by carbon monoxide:

How to Extract Iron from Hematite: Methods and Plants

2023年2月15日 Coarsegrained hematite refers to iron ore with an embedded particle size of 2mm or more It is easy to extract iron from this kind of haematite by using gravity separation and magnetic separation Mediumgrained hematite refers to iron ore with an embedded particle size between 002 and 2mm This type of hematite is also relatively easy to

The six main steps of iron ore processing Multotec

The best advice that we at Multotec can give you is to use products specially adapted to iron processing and also get to know your machines Our team of experts can help you with any questions you may have about cyclones, spirals, drums and samplers, and provide support during the stages of iron ore processing Iron Ore Flow Sheet

Flotation Process and Techniques Involved in Iron Ore

2024年2月29日 The Iron oxide particles stick to the air bubbles and float The floated and concentrated iron ore slurry is then skimmed from the surface of the water and removed by using a filter press If the desired iron content is not achieved, then process is again repeated A “Modifier” process is added in some cases inorder to

Cast Iron Explained: How's It Made, Casting Methods, Types

5 天之前 Cast iron is made by melting iron and adding carbon and other elements to the molten metal, which is then poured into a mold to cool and solidify Here are the basic steps involved in making cast iron: Melting the iron: The first step in making cast iron is to melt iron in a furnace at temperatures of around 2,800 degrees Fahrenheit The iron

Iron Ore Characterization Techniques in Mineral

2023年4月27日 well as ore processing Keywords Iron ore Characterization SEM–EDS XRD XRF FTIR Introduction The most common element that makes up rock formations is iron, which accounts for about 5 percent of the earth’s crust India alone has a signicant reserve of iron ore in the world [1] The two most common iron minerals, hema

Full article: Iron ore processing Taylor Francis Online

2016年8月24日 This special issue of Mineral Processing and Extractive Metallurgy presents a selection of the best metallurgy papers delivered at the very successful international ‘Iron Ore 2015’ conference held at the Perth Convention and Exhibition Centre, Australia, on 10–12 July 2015 This was the seventh in the series of biennial conferences featuring recent

The four steps of iron working: 1 (extraction), 2

The four steps of iron working: 1 (extraction), 2 (smelting), 3 (primary smithing), and 4 (secondary smithing or forging) of the iron, with the involved raw materials and resulting products as

Iron Ore production in the Pilbara Rio Tinto

2023年6月2日 Activities involved in finding, mining and processing iron ore at our Pilbara operations have been simplified in the following diagram Rio Tinto operates 11 iron ore mines in the Pilbara and the specific sequence of activities varies from mine to mine Excellence in planning, scheduling and quality control are fundamental to the process

Process of steelmaking Tata Steel

2 天之前 When sufficient hot metal has formed at the bottom of the furnace, we drill open the furnace and tap the iron The hot metal is collected in torpedoshaped train waggons and is then ready for transport to the BOS (Basic Oxygen Steelmaking) plant next door The converter in the BOS Plant turns the pig iron into steel

How to process iron ore SANDMINE

2024年1月19日 The following is an introduction to the steps of iron ore processing: Pure magnetite can be directly put into the furnace to make iron, but after all, there are still more associated ores For some magnetite with relatively high impurity content, simple crushing and screening, grinding and magnetic separation are required to produce concentrate

A Visual Guide: Steel Making Process Chart Cabaro Group

2024年3月17日 The transformation of iron ore into steel is a remarkable process that involves a series of detailed steps Beginning with the extraction of iron ore from the earth through mining operations, this raw material is then treated and prepared for the smelting phase The extracted ore undergoes processes such as crushing, grinding, and concentration

Iron Ore Processing, General Springer

2022年10月19日 Making iron and steel from iron ore requires a long process of mining, crushing, separating, concentrating, mixing, agglomeration (sintering and pelletizing), and shipping to steel mills Iron ore processing is characterized by a constant adaptation to changing raw materials and market conditions It is the link between the mined

Iron Ore Processing an overview ScienceDirect Topics

The chronological distribution of the references cited in this paper is given in Fig 1 showing that the main reference material used in this review was published in the decade of the 1960s where there was significant research conducted in the United States on the processing of their iron ores The author is aware of significant publications in Portuguese (Brazilian iron ore industry), in

Ironmaking Process an overview ScienceDirect Topics

The HiQIP (HighQuality Iron Pebble) process is a granular ironmaking method developed by JFE Steel The process manufactures granular iron in an RHF The granular iron has a diameter of 20–40 mm and is shaped like the playing pieces called “stones” used in the Japanese board game of go The development of this process began in 1996 by

Guide to Modern Smelting Processes CED Engineering

2024年4月21日 Early iron smelting was accomplished using charcoal fueled furnaces known as bloomeries Iron's Impact: Iron tools and weapons were harder and more durable than bronze, leading to transformative changes in agriculture, construction, and warfare Iron was the foundation of empires like the Roman Empire, as it enabled the construction of

滑石粉设备雷蒙磨有名的厂家

--菱锰矿欧版矿石

--花岗岩磨粉机,磨粉机

--方解石矿 开采成本方解石矿 开采成本方解石矿 开采成本

--中国稀土先进设备

--浙江石灰石摆式磨解决方案

--石粉机多少钱

--中国品牌矿石磨粉机有限公司

--大型重晶石磨粉机

--淄博博山矿石磨粉机

--镍渣的用途

--高砷方解石矿的处理

--河北白垩摆式磨制造商

--搅拌站布局平面图

--地基开挖岩石粉碎用什么设备

--露天矿用车

--开采片石爆破安全生产预案

--膨润土重钙高岭土磨粉机

--投资石灰石粉碎机冶炼废渣再利用设备大概多少钱

--钙粉加工流程

--磨煤机风管的价格

--四川重钙雷蒙磨生产厂家

--配置的整胎矿石磨粉机

--黎明重工重钙磨粉机雷蒙机图片

--湖北荆门市方解石制粉设备项目现场

--马鞍山悬臂高细立磨生产企业

--石灰石粉碎机冶炼废渣仅一成被再利用新

--沈阳矿石,生产制造

--河北大理石欧版磨粉机项目现场

--浙江建德白垩超细立磨生产案例

--