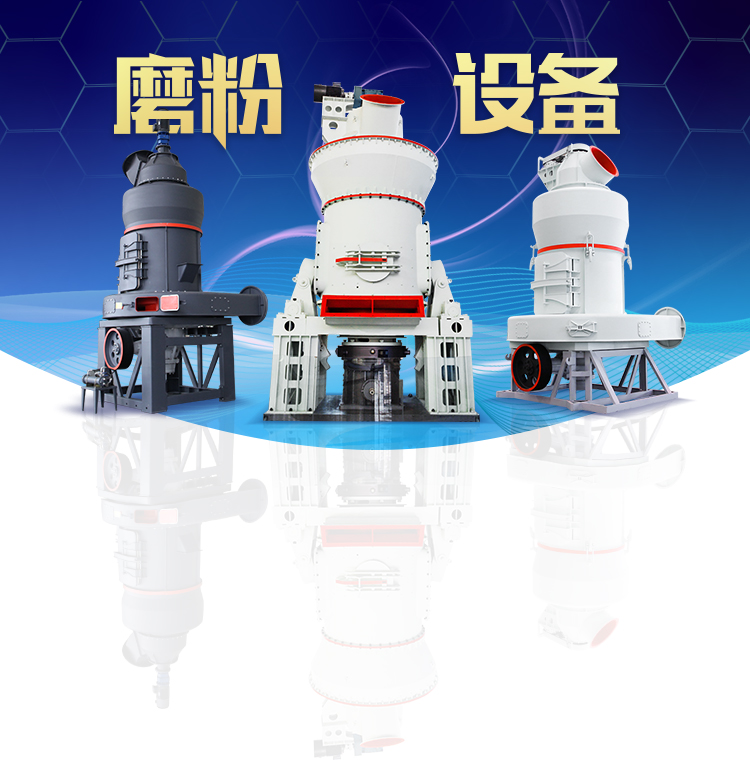

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Hard Liner For Crusher

Crusher Wear Parts and Liners Weir Weir Group

We offer a wide range of cone crusher liner sets and chamber options to suit a variety of crushing applications When evaluating liner replacements, we recommend you change the mantle and bowl at the same time

来自globalweir的其他内容ESCO® Wear Parts and Liners for Trio® Crushers Weir Weir Groupspacingblock" datapriority=>Trio® Wear Parts and Liners for Trio® Crushers Weir Weir GroupCrusher Liners Cone Crusher Liners Crushing

932 行 We supply crusher liners and wear parts with innovative designs and

Crusher Liner MadeinChina

China Crusher Liner wholesale Select 2024 high quality Crusher Liner products in best price from certified Chinese Spare Parts manufacturers, China Crusher suppliers, wholesalers and

Jaw Crusher Liners Foreman Equipment

ESCO® Wear Parts and Liners for Trio® Crushers Weir

2024年5月15日 We offer a wide range of Trio® jaw and cone crusher chambers and liner sets to suit multiple applications, including some of the toughest operating conditions Recommended

标记:Weir, West VirginiaWeir CrushersManganese steel wear liners SRP

Sandvik have a range of liners comprised of different manganese alloys – depending on the material you are crushing, either impact resistance or wear resistance might be a more important consideration for you Each Sandvik

Trio® Wear Parts and Liners for Trio® Crushers Weir Weir

Trio® offer a wide range of cone crusher wear parts and liner sets to suit multiple applications When evaluating liner replacements for your Trio® cone crusher, we recommend that you

标记:Crusher Wear PartsWeir, West VirginiaWeir CrushersCrusher Liners WorldLeading Crusher Liners

CMS Cepcor® stock a wide range of cavity liner options for cone crushers along with many jaw plate tooth profile options for jaw crushers and various metallurgies for impact crushers

标记:Crusher LinersMining EngineeringMining EquipmentCms Cepcor LimitedShell Liners Crusher and Mill Liners CITIC HIC

2024年10月15日 CITIC HIC has a wear liner production base with annual capacity of 30,000 tons of wearresistant castings At the production base, we can produce a variety of wear liners for crushers, grinding mills and vertical stirred

标记:Mining EngineeringCrusher LinersMining EquipmentCITIC HICCrusher Liner Solutions Bradken

Crusher Liner Soutions Bradken’s crusher liner product range is designed to provide the safest solutions for product installation and materials handling, optimal performance in product and operations, and are supported by

标记:CrusherBradkenCone crusher performance liners Wear parts and process

2019年8月16日 hard material during operation, helping material move down and reducing localised wear The performance liners are designed to reduce the peak forces transmitted into the crusher during operation in hard ore applications Because of this, the crusher's internal components experience less stress, helping to increase the crusher's reliability

Ultimate Guide to Cone Crusher Liners:

2023年2月21日 Cone crushers are commonly used in the mining and aggregates industries to reduce the size of raw materials, such as rocks and minerals These machines are powerful, efficient, and versatile, but they rely

Chute Liners designed manufactured by

Chute Liners designed manufactured by Makuri Technology to optimize the front end of hard rock mining Chute Liners, Rom Bins, Dump Pockets All the above has significant effects on not only the crushed product performance of

Crusher Wear Parts Selection Guide For Cones, Jaws, Impactors

2021年8月8日 Cone crusher liners cavity selection Different brands of cone crushers, different cone crusher liners cavity types There are some famous brands of cone crusher liners cavity types: Metso cone crusher liners cavity; Sandvik cone crusher liners cavity; Terex cone crusher liners cavity; Metso cone crusher liners cavity Extra coarse cavity

Wearalloy® Steel Crusher Liners Crusher Wear Liner

Ford Steel offers Wearalloy® 400, 450, 500, Nickel Chrome Plus Plate and Mangalloy® plate up to 4inches thick for Wearalloy® steel crusher liners in impact, jaw, cone and other types of crushers Wearalloy® Superclad available for use as cheek plates too Our company provides crusher wear liner supplies to a wide range of industries including: Sand Gravel

Crusher Liner Plates for High Chromium EB Castworld

Crusher Liner Plates for High Chromium Material: High Chrome Cast Iron Ni Hard White Iron Dimensions: as per drawings Special Features: We adopt Sand Cast Process to make High Cr Ni hard mill machine cooling plate We do quenching tempering treatment for high Cr Ni hard white iron plates to achieve high hardness

Crusher Hammers for CrMo Alloy Steel EB Castworld

Crusher Hammers Structure and characteristics: Center of gravity of the Crusher Hammers head of the hammer crusher moves outward in the radius of gyration, and the linear speed of the hammer head increases during operation Impact energy of the hammer head of the hammer crusher on the material is increased, thereby improving the crushing effect

Manganese Crusher Liners Mining Wear Parts

Our aftermarket manganese crusher liners are designed to optimise your crusher's performance and operating life +61 1300 898 159; ; About Us; Products Manganese Crusher Liners the life of our castings we often add special metals such as Molybdenum to make the casting tougher in situations of hard and abrasive

Mantle Concave and Bowl liner for Cone Crusher

Main materials: high manganese steel, manganesechromium alloy (Mn13, Mn13Cr2, Mn18, Mn18Cr2), hard alloy or customized materials Main technology: water glass sand casting and lost foam casting process Cone crusher linerfind the right solution for your application With our knowledge as an original equipment manufacturer (OEM), we ensure

Jaw Plates: Everything You Should Know Crusher Wear

2023年2月16日 For example, if the crusher is crushing hard and abrasive materials like granite or basalt, it may be more appropriate to choose jaw plates made of high chrome iron or manganese steel On the other hand, if the crusher is crushing less abrasive materials, like limestone or shale, a lowercost option like carbon steel may be suitable

Nihard Iron Mill Liners Wear Parts For Industry Qiming

2 天之前 When it comes to Nihard iron mill liner, Qiming Casting is one of the largest Nihard iron cast foundries Qiming casting has been manufacturing and supplying wear parts for over 10 years 0086 152 5174 4209

Crusher Wear Parts Liners for Impact Crushers

Protect your crusher with impactresistant crusher wear parts and crusher liners made from Clifton Steel's abrasionresistant steel 18007453962 [ protected] Shipping

A Guide to Types of Jaw Crushers for Crushing

2023年2月15日 The Dodge jaw crusher has a variable feed area and a fixed discharge area, which leads to choking of the crusher and is not ideal for hard materials Construction and Design: The Blake jaw crusher consists of a

How to choose the right tooth types for crusher jaw plates?

2020年12月23日 Cone Crusher Head Center; Cone Crusher Locking Nut; Cone Crusher Adjustment Ring; Cone Crusher Main Frame; Mill Liners Ball Mill Liner; AG/SAG Mill Liners; Manganese Mill Liners; Cr Mo Alloy Steel Mill Liners; Chromium Alloy Steel Mill liners; NiHard Mill Liners; Apron Feeder Pans

A Comprehensive Guide to Different Types of Crusher Wear

2023年2月15日 Liner plates can have different designs, such as corrugated or smooth, depending on the type of material being crushed Gyratory Crusher Wear Parts Gyratory crusher wear parts are primarily made up of mantles, concaves, spider arm liners, and rim liners Mantles and concaves are similar to those used in cone crushers, but they are larger and

Gyratory Crusher Liners Crusher Wear Parts by Qiming

6 天之前 The Benefits of Using Titanium Carbide as Crusher Liners; Qiming Casting has developed TIC inserts manganese steel gyratory crusher mantle that is ideal for crushing hard stones For the gyratory crusher concave segments, different areas require different liners The concave segments are divided into three areas: upper intake liners

Crusher Liner WALDUN Crusher Wear Liner Mining

2024年11月6日 WALDUN Crusher liner is in the interior of the crusher and belongs to the consumable equipment That is, in the work time, the internal parts with the extension of working time, in the gradual wear and tear, when the wear reached a certain degree, the equipment can no longer work smoothly The lining plate in the material can play a role in the

ESCO® Wear Parts and Liners for Trio® Crushers Weir

2024年5月15日 ESCO's wide range of Trio® cone crusher liners contain superior alloy recipes (typically a combination of chrome, manganese and carbon) that provide enhanced durability and wear life compared to competing offerings It is also used to process hard rock, sand, concrete, asphalt and slag within the aggregates industry Recommended Industries

Jaw Crusher Liner Plate Design Profile Shapes

2015年7月23日 Straight Jaw Plates: A shows a diagram of a standard type of Blake crusher with regular or straight jaw plates This type of plate has been the standard from the time of its inception, emulating, in this respect, the straight concaves in the gyratory machine

NiHard Mill Liners For Cement Industry From Qiming

Nihard steel standard is ASTM A532 Type 1, Type 2, and Type 4 For mill liners, our foundry uses ASTM A532 Type 4 to cast NiHard Mill Liners Material Chemical Composition The role of different chemical elements in Nihard mill liners:

Crusher Wear Parts for High Chrome EB

EB specializes in Crusher Wear Parts Ni Hard Liners for 20 years We adopt cast process, send cast processs and so on The Combined Selffastened Boltless Crusher Wear Parts Liners It includes two parts, high wear resistance boltless

Trio® Wear Parts and Liners for Trio® Crushers Weir Weir

To ensure that your Trio® jaw crusher continues to perform at its optimum crushing capacity, we offer a diverse range of Trio® crusher wear parts, chamber options and liners to suit various crushing applications Tooth Profile The Trio® tooth profile has been engineered to deliver increased performance in the toughest applications Its shape has been expertly designed to

A Comprehensive Guide to Cone Crusher Parts

2024年11月24日 In addition to standard manganese liners (Mn14, Mn18, Mn22), Qiming Machinery also provides wear parts made from a variety of materials to meet the diverse needs of their customers TIC inserts cone crusher liners for

Mill Liners Manufacturer MGS Casting

When it comes to mill liners, MGS Casting is a Chineseleading manufacturer of mill liners and trommels that improve grinding efficiency, reduce downtime, and lead to increased profitability, which specializes in the design, manufacture and aftersales service and support and is a proven provider of total mill lining solutions across the globe

ESCO Weir Group

2022年12月1日 • Cone parts, jaw crusher liners, gyradisc liners, gyratory concaves and mantles Alloy 14R: high manganese chrome bearing alloy primary or wet crushing, and hard or excessively abrasive media, MAXBAK II HiImpact Crusher Backing offers excellent performance ECOBAK™II HiImpact Crusher Backing is an alternative to

Selecting Jaw Crusher Liners Shape Design

2014年4月7日 A client needed finer crush out of his Jaw Crushers I proposed this literature from Metso to help him select a jaw liner set Designing your jaw crusher liners for the right function starts with asking ‘what final product crush size distribution do I want’ ‘what are the physical characteristics of the feed to that crusher’?

Cone Crusher Liners For Popular Brands With Various Material

2024年11月24日 Cone crusher liners mainly wear parts in the cone crusher, which are included cone crusher mantle and cone crusher concave Cone crusher mantle, which covers the cone head of the crusher to protect it from wear When crushing hard stone, the manganese steel mantle and concave can not work for a long time Even the Mn22Cr2 cone crusher liner

Cone Crusher Liners EB Castworld

Cone Crusher Liner has the characteristics of beautiful appearance, high internal quality, resistance to emptiness, wear, extrusion, and long service life It fully meets the requirements of the concentrator for the use of Cone Crusher Liner: Cone Crusher Liners are the main components for crushing materials in the cone crusher

Impact crusher parts Metso

The impact crusher parts range consists of spare parts and wear parts We also offer wear parts lifting tools to ensure an efficient and safe liner changeout for your impact crusher Crusher wear part lifting tools > Component replacement labour service > Parts planning, inspections and extended warranties

Cone crusher performance liners Wear parts and process

2019年8月16日 hard material during operation, helping material move down and reducing localised wear The performance liners are designed to reduce the peak forces transmitted into the crusher during operation in hard ore applications Because of this, the crusher's internal components experience less stress, helping to increase the crusher's reliability

Ultimate Guide to Cone Crusher Liners:

2023年2月21日 Cone crushers are commonly used in the mining and aggregates industries to reduce the size of raw materials, such as rocks and minerals These machines are powerful, efficient, and versatile, but they rely

Chute Liners designed manufactured by

Chute Liners designed manufactured by Makuri Technology to optimize the front end of hard rock mining Chute Liners, Rom Bins, Dump Pockets All the above has significant effects on not only the crushed product performance of

Crusher Wear Parts Selection Guide For Cones, Jaws, Impactors

2021年8月8日 Cone crusher liners cavity selection Different brands of cone crushers, different cone crusher liners cavity types There are some famous brands of cone crusher liners cavity types: Metso cone crusher liners cavity; Sandvik cone crusher liners cavity; Terex cone crusher liners cavity; Metso cone crusher liners cavity Extra coarse cavity

Wearalloy® Steel Crusher Liners Crusher Wear Liner

Ford Steel offers Wearalloy® 400, 450, 500, Nickel Chrome Plus Plate and Mangalloy® plate up to 4inches thick for Wearalloy® steel crusher liners in impact, jaw, cone and other types of crushers Wearalloy® Superclad available for use as cheek plates too Our company provides crusher wear liner supplies to a wide range of industries including: Sand Gravel

Crusher Liner Plates for High Chromium EB Castworld

Crusher Liner Plates for High Chromium Material: High Chrome Cast Iron Ni Hard White Iron Dimensions: as per drawings Special Features: We adopt Sand Cast Process to make High Cr Ni hard mill machine cooling plate We do quenching tempering treatment for high Cr Ni hard white iron plates to achieve high hardness

Crusher Hammers for CrMo Alloy Steel EB Castworld

Crusher Hammers Structure and characteristics: Center of gravity of the Crusher Hammers head of the hammer crusher moves outward in the radius of gyration, and the linear speed of the hammer head increases during operation Impact energy of the hammer head of the hammer crusher on the material is increased, thereby improving the crushing effect

Manganese Crusher Liners Mining Wear Parts

Our aftermarket manganese crusher liners are designed to optimise your crusher's performance and operating life +61 1300 898 159; ; About Us; Products Manganese Crusher Liners the life of our castings we often add special metals such as Molybdenum to make the casting tougher in situations of hard and abrasive

Mantle Concave and Bowl liner for Cone Crusher

Main materials: high manganese steel, manganesechromium alloy (Mn13, Mn13Cr2, Mn18, Mn18Cr2), hard alloy or customized materials Main technology: water glass sand casting and lost foam casting process Cone crusher linerfind the right solution for your application With our knowledge as an original equipment manufacturer (OEM), we ensure

Jaw Plates: Everything You Should Know Crusher Wear

2023年2月16日 For example, if the crusher is crushing hard and abrasive materials like granite or basalt, it may be more appropriate to choose jaw plates made of high chrome iron or manganese steel On the other hand, if the crusher is crushing less abrasive materials, like limestone or shale, a lowercost option like carbon steel may be suitable

西安沥青混凝土路面价格

--陕西省平利县重晶石粉厂

--15p粉碎机

--怎么粉磨生石灰石

--方解石矿制酸装备单位投资额

--内蒙古额济纳旗膨润土证办理

--请问成都哪里有磨粉机卖?

--湖北粉碎机

--2014 Unique High Efficiency Jaw Crusher For Sale

--重晶石磨粉机gs技术参数

--矿业有限公司土地使用税要交吗

--时产340方裂解炭黑立式石灰石雷蒙磨

--股份矿石制粉场承包经营合同股份矿石制粉场承包经营合同股份矿石制粉场承包经营合同

--立式磨矿石磨粉机维修保养常识

--矿渣制粉加工设备价格

--英国粉碎机

--想开个小型工厂

--MSB粉碎機

--矿物片粉碎机

--菱镁矿Z椰壳活性炭制粉机械重晶石磨粉机价格

--石场大型立磨立式辊磨机维修石场大型立磨立式辊磨机维修石场大型立磨立式辊磨机维修

--夜压方解石大型立磨立式辊磨机

--宁德重钙粉

--沈阳矿山机器厂

--安徽池州白云石悬辊磨全套设备价格

--总共500多米的长度防爆的

--信阳立磨

--立磨机上海

--永州粉磨方解石矿加工设备

--超细硫酸钡矿物磨粉机械多少钱一台

--